Electronics is one of the industrial sectors with the greatest impact on the environment in terms of CO2 emissions and waste. Since 2020, the government « France Relance » plan has been

Applications for GenesInk products are numerous in the field of printed electronics, IoT, energy and mobility.

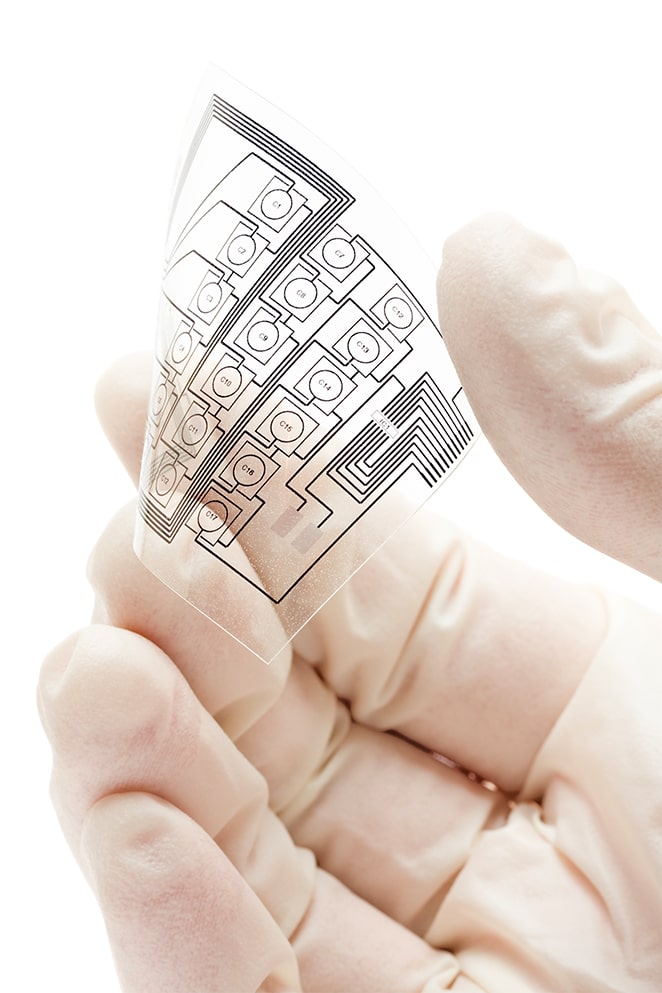

GenesInk offers our customers a full range of nano-solutions enabling the development of new devices :

– Connected devices such as glasses, windows, watches, hearing aids, medical devices, office supplies

– RFID, LoRa, SigFox antennas

– Flexible PCBs and sensors

– Biosensors

– In-Mold Electronics for automotive and appliances

– Shielding

– ITO substrates

– Displays

– Solar cells (organics and perovskite),

– OLEDs