Electronics is one of the industrial sectors with the greatest impact on the environment in terms of CO2 emissions and waste. Since 2020, the government « France Relance » plan has been

FAQ

- Standard mask works well with Smart Screen product. Depending on your requirements, screen printing mask has to be adjusted. You can find examples on the TDS. GenesInk team provide printing support and share printing conditions to help customers to use our products in the best way.

- We have adjusted our formulas to be adapted to each printing processes. No need to modify the ink prior to printing. You can contact us for specific demands.

- GenesInk has developed cleaning solutions dedicated to each ink avoiding risk of chemical reaction with nanoparticles. We highly recommend using our cleaning solution to increase your printer shelf life.

- There are no dangers related to nanoparticles inhalation. Indeed, there is no risk of particle release in atmosphere as long as nanoparticles are in a wet media. Once printed and cured, particles are sintered and therefore no longer nano sized. The use our products require standard personal protective equipment (PPE) for chemical products. For more details, please refer to the MSDS.

- Silver can get oxidized. To avoid that, we recommend printing a protection layer on top of the silver layer. We have developed a specific product called ProtectInk S (P-ID21001) allowing to avoid oxidation and scratches of the silver. No electrical modifications after 1 000h at 85°C/85%RH of the silver when protected with this product.

- The main difference come from the particles size. Thanks to the nano size, the electrical performances of GenesInk solutions are 10 times better than silver pastes. It helps reducing consumption of raw materials and decrease the cost of printed electronic production (total cost of ownership).

- GenesInk conductive nano-silver inks provide:

- Unrivaled conductivity

- Unbeaten ease of process

- Low temperature curing

- Ease to clean

- CMR free (no toxic components)

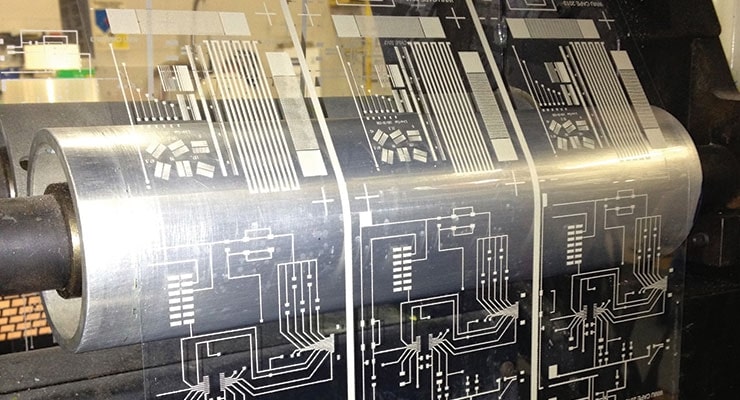

- S-CS21303 is our standard screen-printing formula. This ink has been designed to provide high conductivity (resistivity down to 2.5 µOhm.cm) and has a lower viscosity. This ink should be used to obtain lines width > 80 microns.

- S-CS21306 has been designed for application requiring high resolution (down to 40 µm line width). This ink should be used to obtain line width < 80 µm. For more details, please see the associated TDS.

- 40 µm line width can be achieved by screen printing using our Smart Screen R ink. For more details, please see the associated TDS.

- There is no variation of electrical performances observed after bending down to 2mm of bending radius.

- It is PA ink.

- We recommend using a conductive glue.

- There are two types of conductive glue used with our inks :

- Anisotropic adhesive – DELO MONOPOX AC245 – (datasheet) for complex component footprint

- Isotropic adhesive – DELO DUALBOND IC343 – (datasheet) for basic component

- Solder is possible in specific conditions.

- Durability tests were performed on printed sheets of Smart Screen F S-CS21303. Samples were left at 85°C and 85% humidity for 1000 hours and showed no changes in resistivity, adhesion and appearance.

- Viscosity of ink can be decreased by heating the printhead up to 35°C. The viscosity of CS01130 heated to 35°C will decrease from 12,5 mPa.s to 7 mPa.s.

- Each ZnO/AZO ink can be dry with the same conditions.

- We recommend drying inks between 80°C and 120°C during 5mn or 10 mn depending on the drying temperature.

- The ZnO is a N type semi-conductor.

- Improvement of the conductivity of ZnO if annealed at a temperature >180°C

- A pre-drying at room temperature must be done before annealing to avoid the migration of solvents that have too different boiling point temperatures

Would you not be able to find the answer to your question in our FAQ send your question here

About us

GenesInk is an industrial producer of nano metals and metal oxide inks, headquartered in the south of France with sales offices in Japan and in the USA. With 10 patent families granted and more than 60 national patents, we run a production unit for ton scale manufacturing.

- 39 avenue Gaston Imbert, ZI Rousset,

13106 Rousset Cedex

Recent news

© 2024 - genesink.com | General Terms & Conditions | Confidentiality Agreement