Electronics is one of the industrial sectors with the greatest impact on the environment in terms of CO2 emissions and waste. Since 2020, the government « France Relance » plan has been

The overall display market is evolving quickly and is expected to grow from US$138 billion in 2019 to US$168 billion by 2024. In fact, the display industry is witnessing several developments with the commercialization of new display technologies based on micro-LEDs and quantum dots (QD).

LCDs (Liquid Crystal Displays) based on a-Si glass backplanes are still the dominant display technology (90% of displays sold) but several more challenging display technologies are being adopted by large companies such as Samsung, Microsoft, LG and Asus. Conformable OLED displays are found in a variety of commercial products nowadays, such as the Samsung Galaxy Edge and smart watches. Samsung and Apple are already presenting flexible phones incorporating flexible displays. OLED display technology offers rich colors, high contrast, deep blacks, a wide viewing angle, low power consumption and fast response time. Compared to LCDs, OLED displays have the following advantages:

– Enhanced image quality – improved contrast, wider viewing angle, advanced brightness, a wider color range and much faster refresh rates.

-Lower power consumption.

-Ultra-thin, flexible, foldable and transparent displays.

– Better durability and stability – OLEDs are very durable and can operate in a broader temperature range.

Following key parameters are considered among the most important regarding flexible OLED displays:

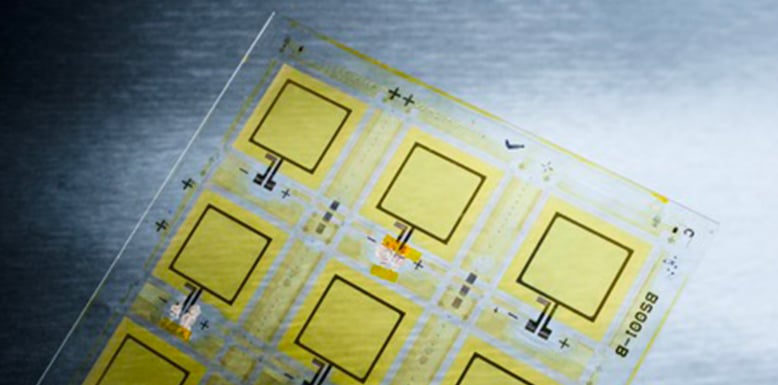

– Bend radius: the radius to which the device can be bent 1000 times without a significant loss of performance. TranDuctive® transparent conductive inks by GenesInk offer a solution for transparent electrodes allowing a bending radius of 2 mm.

– Lifetime: GenesInk offers the display market inorganic conductive and semi-conductive inks that allow access to high mechanical and chemical stability against oxidation, temperature and humidity.

– Transparency: GenesInk’s product line for display applications allow users to reach high transparencies close to or even higher than 90%.

-Semiconductor mobility: High carrier mobility is necessary for high resolution displays and high brightness OLED applications. GenesInk offers a range of high mobility semi-conductors.

– Operational temperature range: GenesInk offers a wide range of inorganic conductive and semi-conductive materials that operate and perform from 60°C to temperatures higher than 300°C. This makes GenesInk’s nano-inks adaptable for various types of substrates and display applications especially when higher temperature processing is required, for example in automotive flexible display applications.

Transparent conductive films find applications in various fields such as displays and OLEDs.