Electronics is one of the industrial sectors with the greatest impact on the environment in terms of CO2 emissions and waste. Since 2020, the government « France Relance » plan has been

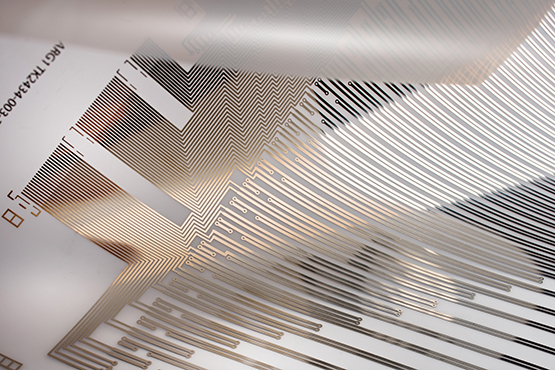

Conductive ink : Join the IoT revolution with innovative and flexible applications

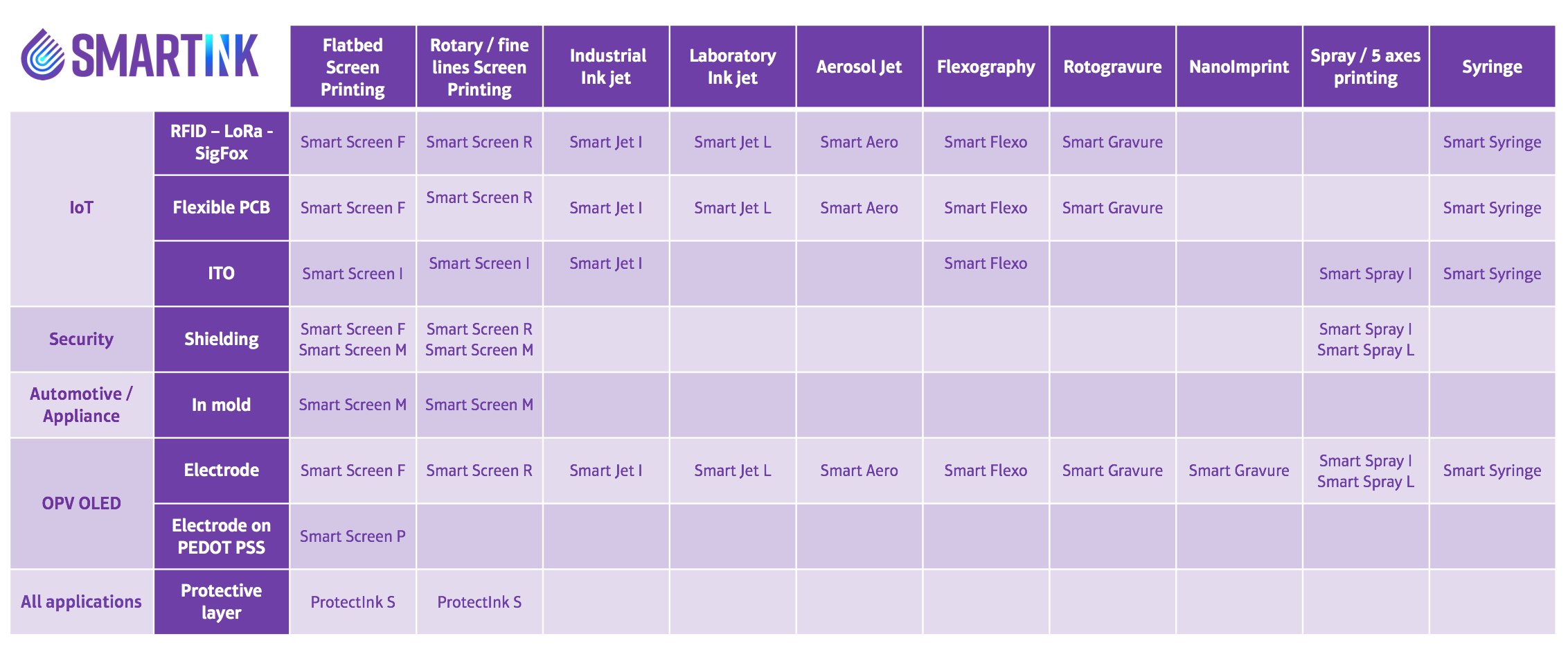

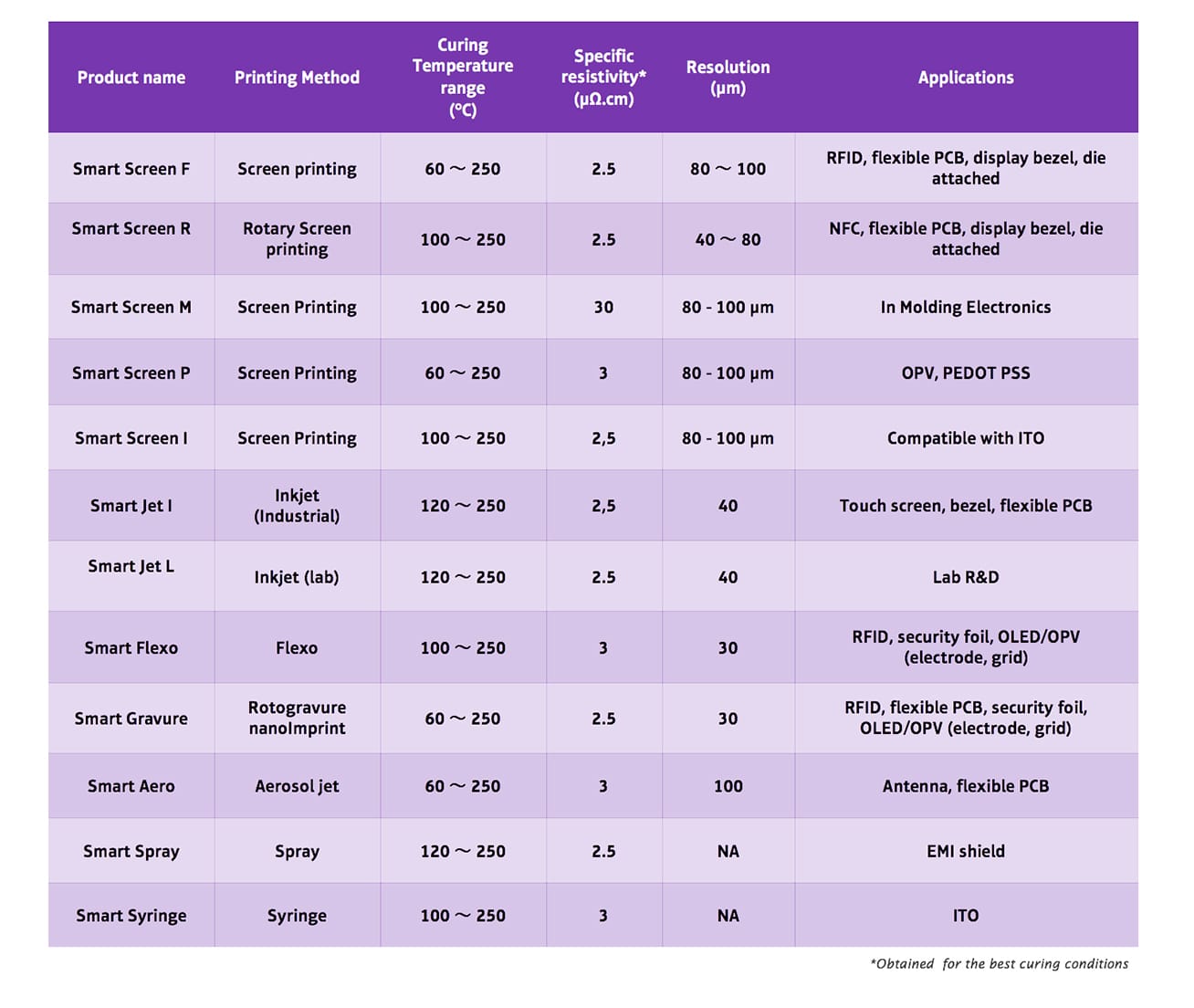

SmartInk products are the right solutions for the printing of highly conductive and flexible circuits. SmartInk products are cured at low temperatures, enabling the use of flexible substrates (polyimide, PET, PEN…) and resulting in faster drying and lower sheet resistances than competitive silver products.

Functions :

> Conductive circuits

> Busbars

> Antennas

> Electrodes

> Sensors