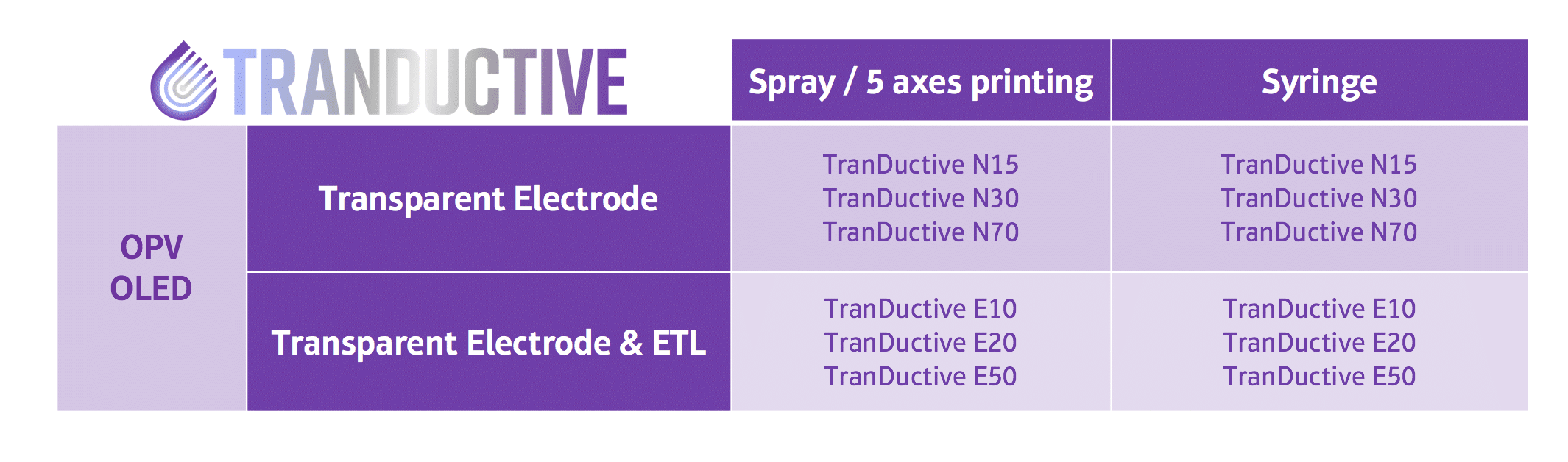

TranDuctive® inks are designed to improve cost processing in manufacturing ETL and transparent conductive layers for OPV, OLED and displays.

ITO has long been the only solution for transparent electrode layer in the OPV, OLED and display industries. Manufacturers depend on a single volatile source of supply with potential shortages in the next future.

GenesInk offers two TranDuctive® ranges as alternative to existing products: high conductivity, high transmission, very smooth surface, easy and homogeneous coating, and safe by design.

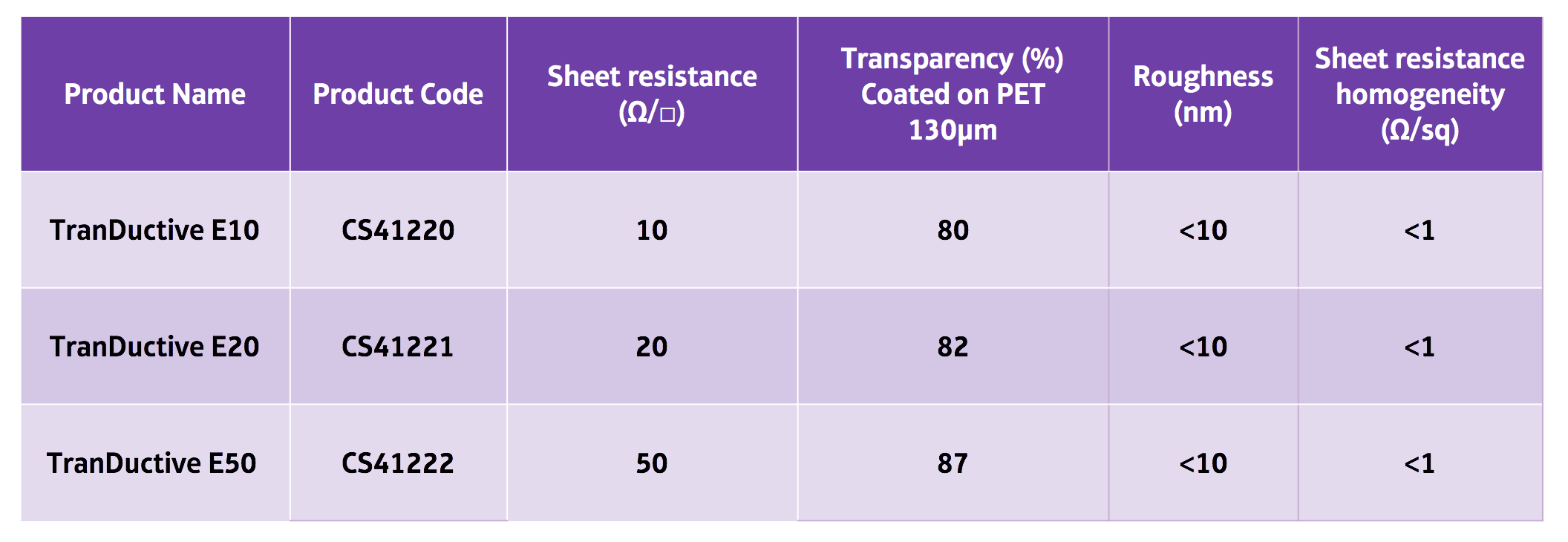

TranDuctive E offers an improved “all in one” solution: ETL + transparent conductive layer for OPV and OLED.

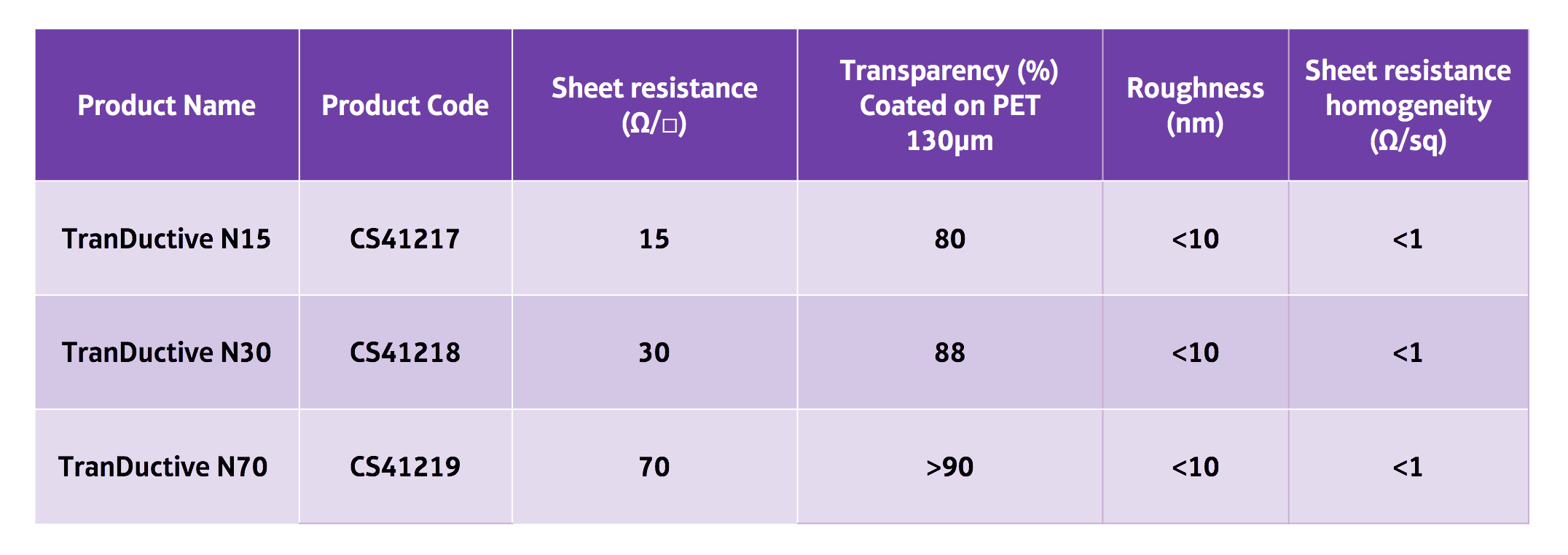

TranDuctive N is a direct alternative to ITO with improvement in processing, durability and flexibility.

Features, Advantages & Benefits