Electronics is one of the industrial sectors with the greatest impact on the environment in terms of CO2 emissions and waste. Since 2020, the government « France Relance » plan has been

A lot of work, but just one word: #Proud. The best is yet to come.

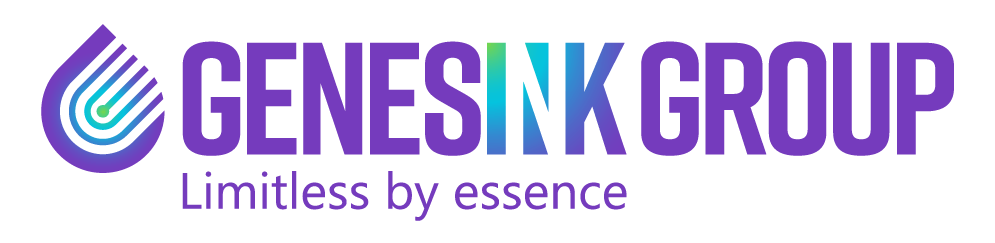

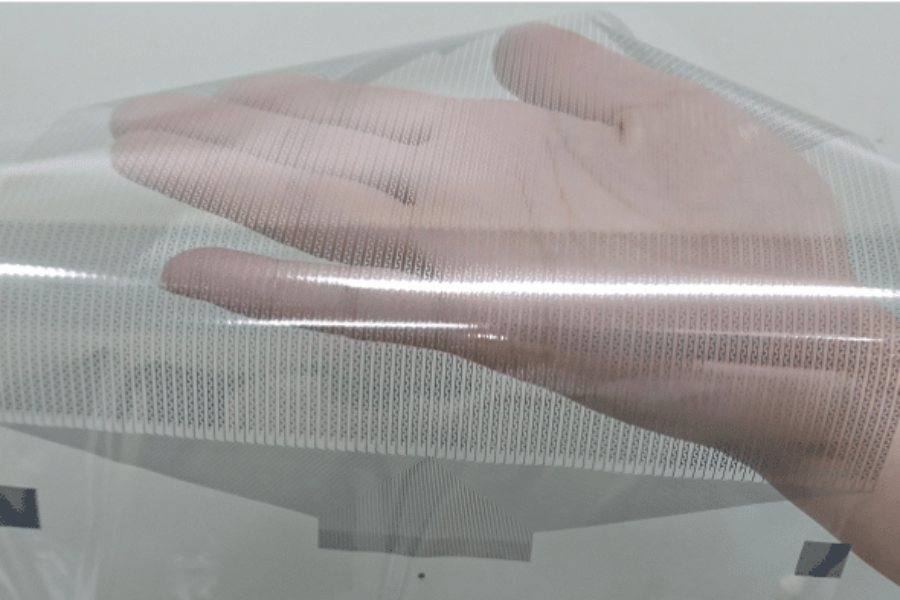

GenesInk develops conductive and semi-conductive inks to enable new functionalities such as transparency, flexibility, and stretchability for the consumer electronics market. What makes GenesInk unique is its capability to solve

GenesInk develops conductive and semi-conductive inks to enable new functionalities such as transparency, flexibility, and stretchability for the consumer electronics market. What makes GenesInk unique is its capability to solve

The research is part of the European MADRAS project which will enable mass production of this type of electronics, known as OLAE, for accelerated time-to-market. Seen as a viable alternative

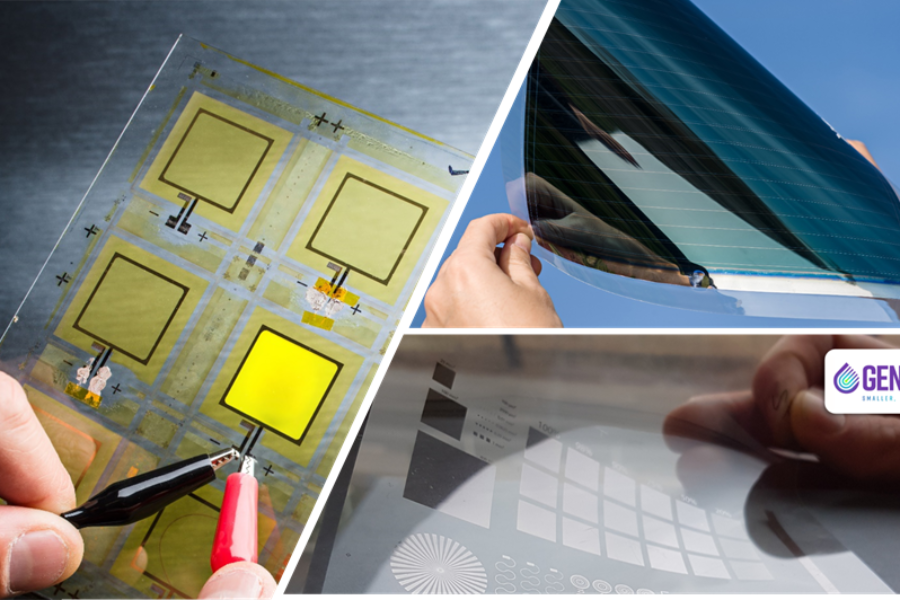

With the increasing European demand for renewable and greener energies, GenesInk develops conductive and semi-conductive nanoinks sustainably for you to create devices of tomorrow and meet the energies market demand

GenesInk reminds you the next webinar on “Smart packaging: GenesInk’s solution to many needs ”. This webinar will give you more information and details on our range dedicated to

GenesInk develops conductive and semi-conductive nanoinks sustainably for aeronautics application. Our nanoinks allow you to create smart integrated antennas on composite and polymer materials by spray coating and printing techniques.

Description du poste et missions Acteur de référence dans la conception et la formulation d’encres de spécialité, notre société GenesInk basée à Rousset (Bouches-du-Rhône) recherche un chef de projet Recherche

Description du poste et missions Acteur de référence dans la conception et la formulation d’encres de spécialité, notre société GenesInk basée à Rousset (Bouches-du-Rhône) recherche un technicien chimiste H/F pour

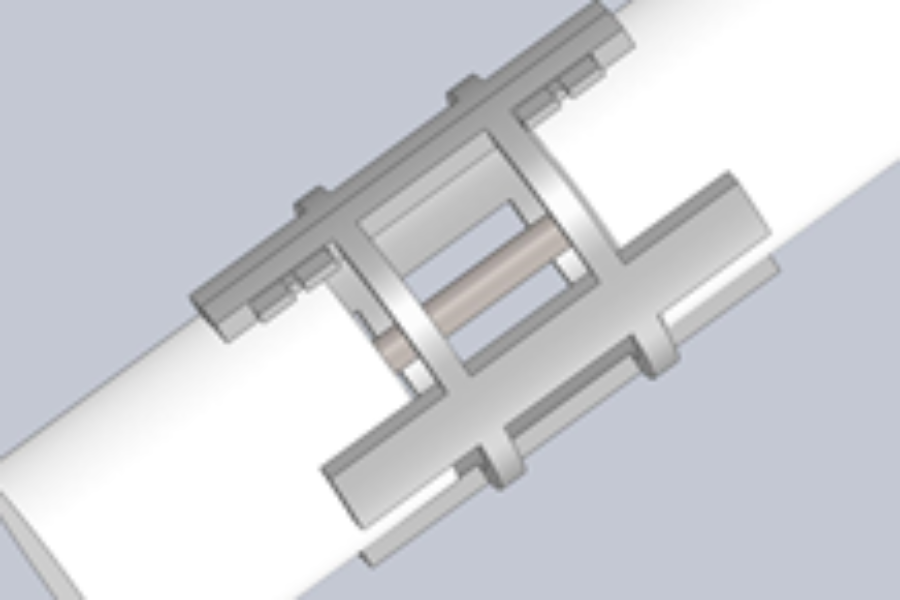

Advanced materials and processing in organic electronics MADRAS project aims to demonstrate a materials-driven improvement of OLAE devices, establishing a high speed manufacturing methodology in a scalable competitive

Smart Bone Regeneration The SBR project brings together experts from medicine, biochemical, pharmaceutical, and material sciences, engineering and industry for solving an unmet challenge in the management of bone loss

Project TEESMAT – Open innovation test bed for electrochemical energy storage materials Despite more than 200 years of development of batteries, the physical limits of battery performance are far from

GenesInk continues its expansion in Asia and is pleased to announce the opening of its new office on June 1st in Taipei, the capital of Taiwan. This office marks the

Project GREENSENSE – Sustainable, Wireless, Autonomous Nanocellulose-based Quantitative DoA Biosensing Platform Paper-based printed electronics are new recyclable electronic devices with technical, economic and environmental advantages. Additionally, nanocellulose (NC) based printed